Miscellaneous Machines

Miscellaneous industrial machines include presses, press brakes, and stamping equipment for mechanical and hydraulic operations across various production workflows.

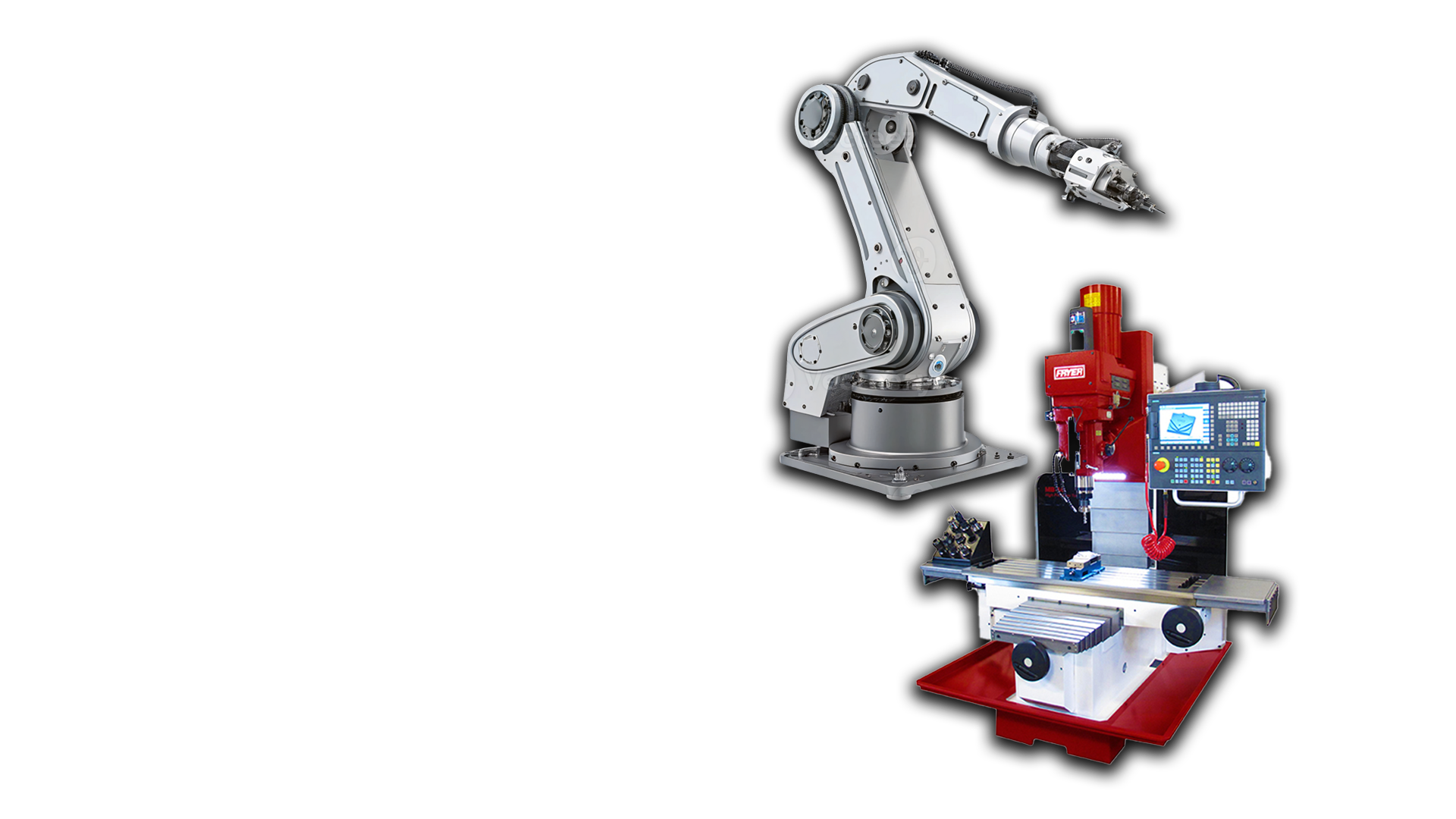

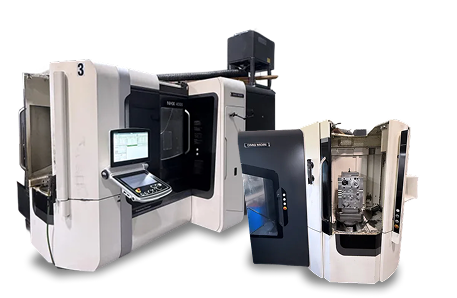

Industrial Automation & Support Equipment

Industrial automation and support equipment includes machines and systems that enhance manufacturing efficiency, accuracy, and productivity across machining and fabrication operations. This category includes robotic arms, 3D printers, material handling systems, inspection equipment such as coordinate measuring machines (CMMs), tooling and workholding solutions, air compressors, and finishing systems.

These machines support production workflows by automating repetitive tasks, improving quality control, and streamlining material movement. Browse our current inventory of industrial automation and support equipment for sale below.

All Machines (0)

Industrial Automation & Support Equipment

Industrial automation and support equipment plays a vital role in modern manufacturing by enabling efficient workflows, consistent quality, and scalable production. While CNC machines and fabrication equipment perform the core machining operations, support equipment ensures those processes run smoothly, safely, and accurately.

From robotics and inspection systems to tooling, material handling, and finishing solutions, these machines are essential for optimizing production environments in both job shops and large-scale manufacturing facilities.

Types of Industrial Automation & Support Equipment

This category includes a wide range of machines and systems designed to support manufacturing operations:

Robotic Arms and Automation Systems

Industrial robotic arms are used for machine tending, part loading and unloading, welding, palletizing, and assembly operations. Robots improve consistency, reduce labor requirements, and enable unattended or lights-out production.

3D Printers (Additive Manufacturing)

Industrial 3D printers are used for rapid prototyping, tooling production, fixtures, jigs, and even end-use parts. Additive manufacturing allows manufacturers to shorten lead times and reduce costs for complex or custom components.

Material Handling Equipment

Material handling systems move parts and materials efficiently throughout the production process. This includes conveyors, pallet systems, lifts, and automated handling solutions designed to reduce manual labor and improve shop-floor safety.

Inspection and Metrology Equipment

Inspection machines such as coordinate measuring machines (CMMs) ensure dimensional accuracy and quality control. These systems are critical in industries with tight tolerances, including aerospace, medical, and precision manufacturing.

Tooling and Workholding

Tooling and workholding solutions—including vises, fixtures, rotary tables, and tool holders—are essential for securing parts and tools during machining. Proper workholding improves accuracy, repeatability, and overall machining performance.

Air Compressors

Industrial air compressors provide compressed air for powering tools, machines, and automation systems. Reliable compressed air is essential for CNC machines, fabrication equipment, and pneumatic systems throughout the shop.

Finishing Systems

Finishing equipment includes deburring machines, polishing systems, vibratory finishers, and surface treatment solutions. These machines improve surface quality, remove sharp edges, and prepare parts for final assembly or coating.

Benefits of Automation & Support Equipment

Adding the right automation and support equipment can significantly improve manufacturing performance:

- Increased productivity and throughput

- Improved part consistency and quality

- Reduced labor requirements

- Enhanced shop-floor safety

- Better utilization of CNC and fabrication machines

These systems help manufacturers scale operations without sacrificing precision or efficiency.

Automation & Support Equipment vs Core Machine Tools

While CNC machines and fabrication equipment perform material removal and forming operations, automation and support equipment enable those machines to operate at peak efficiency. Most modern manufacturing facilities rely on a combination of both to remain competitive.

Buying Used Industrial Automation & Support Equipment

Buying used automation and support equipment can be a cost-effective way to expand capabilities. When evaluating used equipment, consider:

- Compatibility with existing machines and processes

- Control systems and software requirements

- Physical footprint and power needs

- Maintenance history and service support

- Integration potential with automation systems

Careful evaluation ensures the equipment will deliver long-term value within your production environment.

We’re Here to Help

Our team sources high-quality used industrial automation and support equipment from manufacturers across the U.S. Whether you’re adding robotics, inspection systems, or essential shop infrastructure, our experts can help you find the right solution for your operation. Contact us today to learn more about current inventory and upcoming equipment - (312) 604-1850

Looking for a Specific Model?

Looking for a specific machine model? Our network can quickly source any make, model, or configuration to align with your production needs and budget.