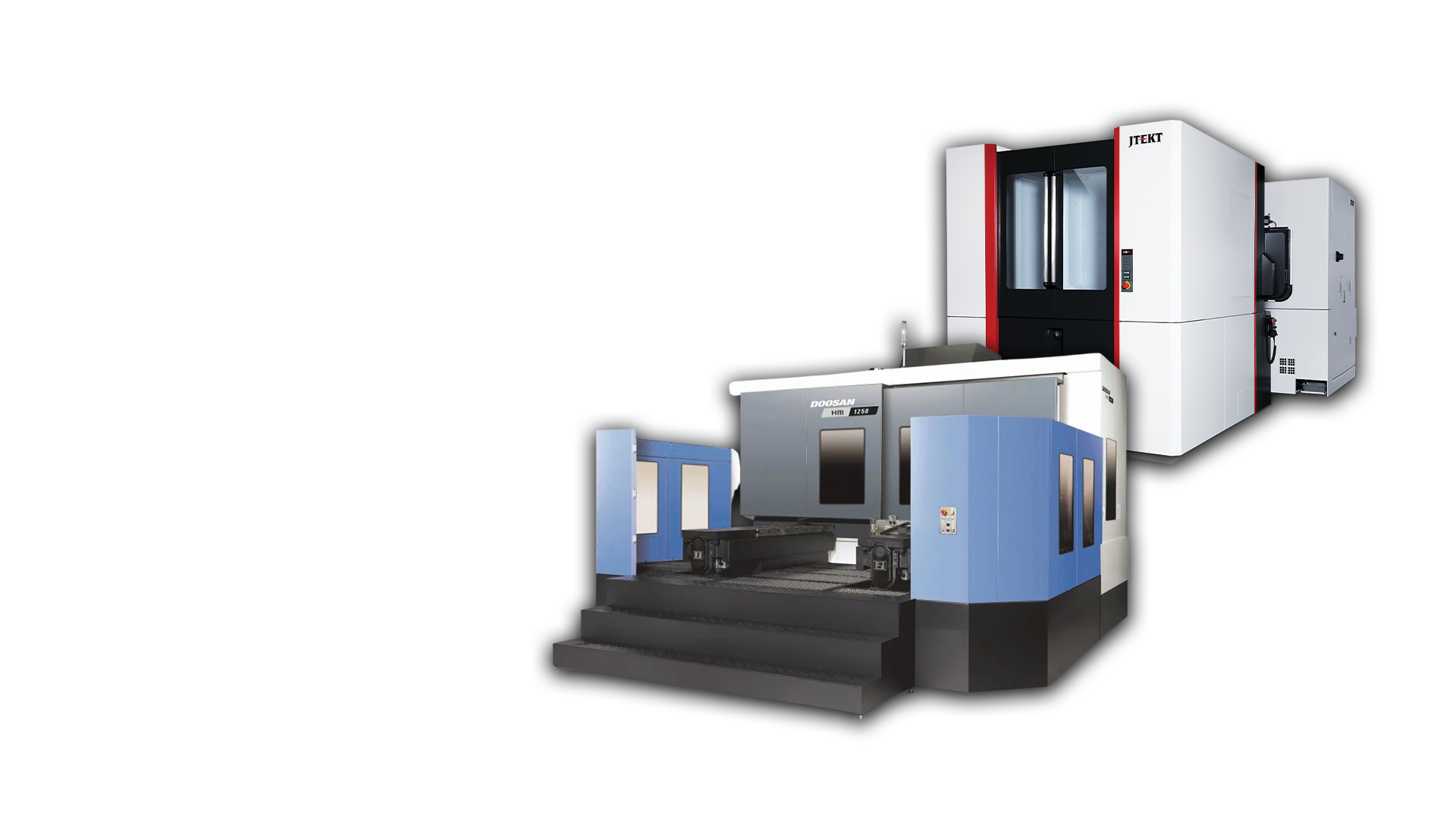

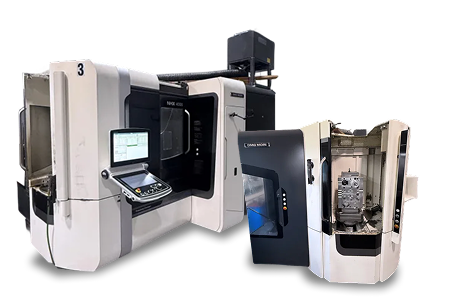

Horizontal Machining Centers

Horizontal Machining Centers (HMCs) are industrial-grade machines designed for precision milling, drilling, and tapping operations with a horizontally oriented spindle.

Horizontal Machining Centers

Horizontal machining centers (HMCs) are CNC milling machines designed for high-efficiency, high-volume production. Featuring a horizontally oriented spindle, HMCs excel at heavy cutting applications, improved chip evacuation, and multi-side machining in a single setup. Horizontal machining centers range from compact 4-axis machines to large-frame production mills with pallet changers, high-torque spindles, and advanced automation options.

Common horizontal machining center manufacturers include Haas, Mazak, Okuma, Makino, DMG Mori, Mori Seiki, Doosan, Toshiba, Kitamura, and OKK. Browse our current inventory of horizontal machining centers for sale below.

All Machines (0)

Horizontal Machining Centers (HMCs)

Horizontal machining centers are designed for manufacturers that demand maximum productivity, repeatability, and efficiency. Unlike vertical machining centers, HMCs use a horizontally mounted spindle that allows gravity-assisted chip evacuation, reducing re-cutting and improving surface finishes. This design makes horizontal machining centers ideal for long production runs, heavy material removal, and complex multi-face parts.

HMCs are commonly used in automotive, aerospace, defense, heavy equipment, and high-volume production environments where spindle utilization and cycle time are critical. With proper programming and automation, a single horizontal machining center can often replace multiple vertical mills.

How Horizontal Machining Centers Work

Most horizontal machining centers are equipped with a 4th axis rotary table, allowing parts to be machined on multiple sides without repositioning. Many machines also include dual pallet changers or multi-pallet systems that enable continuous operation—one pallet can be loaded while the other is being machined.

This configuration dramatically increases spindle uptime, with many HMCs achieving spindle utilization rates of 80–90%, compared to significantly lower utilization on typical vertical machining centers.

Benefits of Horizontal Machining Centers

Horizontal machining centers offer several key advantages over vertical milling machines, particularly in production environments:

- Superior chip evacuation, reducing tool wear and heat buildup

- Higher spindle utilization and shorter cycle times

- Improved surface finishes due to reduced re-cutting

- Increased rigidity for heavy cutting applications

- Multi-side machining in a single setup

- Pallet changers for automated loading and unloading

- Reduced labor requirements per part

These advantages make HMCs a preferred choice for manufacturers producing consistent, high-volume parts with tight tolerances.

Horizontal vs Vertical Machining Centers

While vertical machining centers are often favored for flexibility and lower initial cost, horizontal machining centers excel in throughput and efficiency. An HMC can often outperform multiple VMCs when running production parts, particularly where automation and repeatability are critical.

HMCs typically require a larger upfront investment and more advanced programming skills, but many shops find the cost per part significantly lower over time due to increased productivity and reduced labor costs.

Automation and Pallet Systems

Many horizontal machining centers are designed to integrate seamlessly with automation systems. Pallet changers, pallet pools, robotic loading, and lights-out machining capabilities allow HMCs to run unattended during nights and weekends. This makes horizontal machining centers especially attractive for manufacturers looking to scale production without increasing labor.

Buying a Used Horizontal Machining Center

Purchasing a used horizontal machining center can be a cost-effective way to add high-production capability to your shop. When evaluating a used HMC, consider the following factors:

- Spindle hours and maintenance history

- Condition of the rotary table and pallet changer

- Available automation and pallet capacity

- Control type and software compatibility

- Chip management and coolant systems

- Power requirements and floor space

Comparing similar models and understanding prior applications can help ensure you select the right horizontal machining center for your production needs.

We’re Here to Help

Our team specializes in sourcing high-quality used horizontal machining centers from manufacturers across the U.S. Whether you’re expanding production or upgrading from vertical machining centers, we can help you find the right HMC for your application. Contact our CNC experts today to learn more about current inventory and upcoming machines - (312) 604-1850

Looking for a Specific Model?

Looking for a specific machine model? Our network can quickly source any make, model, or configuration to align with your production needs and budget.